Data-controlled operation

To ensure the safe, trouble-free and efficient operation of a vehicle, key figures such as temperature, humidity and volume of the intake air, wheel speed, position of the camshaft and crankshaft, residual oxygen content in the exhaust gas and many more must be monitored. VDO sensors record this vital data and forward it to the engine control unit in order to reduce fuel consumption and pollutant emissions.

The result? An increase in driving comfort and enjoyment, engine efficiency and driving safety.

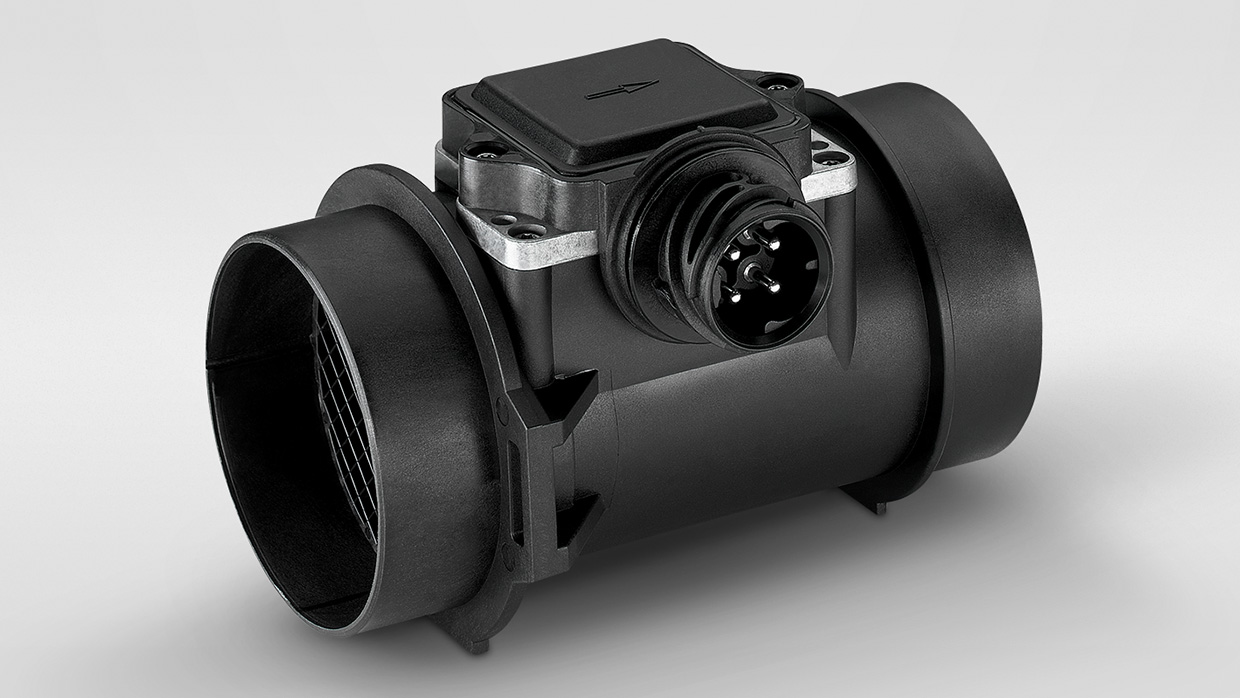

Mass airflow sensors

In the face of mounting restrictions on CO2 emissions, the importance of mass airflow sensors for ensuring optimal mixture ratios is rapidly increasing. Mass airflow sensors are located directly behind the air filter in the intake manifold. They provide information on temperature, humidity and intake air volume.

Despite their very compact design, they are equipped with high-precision technology that can be used to acquire valuable information and link it with additional engine data for perfect engine management.

This information includes:

- the temperature,

- the humidity,

- and the volume of the intake air.

In gasoline engines, the air mass measurement is used in conjunction with other sensor measurements to regulate the fuel supply to the engine. In diesel engines, the mass airflow sensor is used to control the exhaust gas recirculation rate (EGR rate) and to calculate the maximum fuel injection quantity.

Our mass airflow sensors are especially reliable and protected robustly against environmental influences. Thanks to their dynamic measuring capability, they make an important contribution to reducing vehicle emissions.

Camshaft sensors

The camshaft sensor is located in the cylinder head and scans the camshaft sprocket to determine its position.

This information is needed, e.g., to determine the start of injection in sequential injection, for the control signal of the solenoid valve in the pump-nozzle injection system and for cylinder-selective knock control.

Crankshaft sensors

Crankshaft sensors supply information about the current crankshaft position, which the engine management system uses to calculate the rpm. The most economical injection and ignition timing of the vehicle can be calculated using these values.

Knock sensors

Modern engines that enable a high compression ratio have a decisive disadvantage: Their design leads to increased knocking, which can damage the engine.

Knock sensors reliably measure the engine block vibrations characteristic of engine knock. This allows the ignition angle and other operating parameters to be optimally set, enabling the combustion engine to operate close to the knock limit, not only protecting the engine, but also reducing fuel consumption. Our knock sensors already use innovative broadband technology to ensure that the measurement results are as precise as possible.

Pressure sensors

To determine the volume of intake air, MAP and T-MAP sensors measure the air pressure in the intake manifold behind the throttle valve.

This information is particularly important for calculating the amount of fuel to be injected and achieving the correct fuel/air mixture. The dynamic measuring capability of these engine management components has an impact on the reduction of vehicle emissions.

Lambda sensors

Lambda sensors measure the residual oxygen content in the exhaust gas and transmit the measurement to the engine control unit, which then uses it to precisely adjust the fuel/air mixture.

An almost complete conversion into environmentally compatible exhaust gases can only be achieved with an ideally adjusted ratio of air to fuel. Our lambda sensors ensure the best possible engine performance – and they also comply with prescribed emission values.

Exhaust gas temperature sensors

Controlling the exhaust gas temperature is essential for protecting components and ensuring efficiency.

- Temperature monitoring of turbochargers, catalytic converters, diesel particle filters and nitrogen oxide reduction systems

- Protection from temperature overload

- Reduction of pollutant emissions and fuel consumption

Catalog

Please see our online catalog for more information on this product that can be installed in your vehicle (passenger car).