100% dependable operation

VDO products are really in their element when precise control is crucial. Our VDO engine actuators will help you exploit the full potential of modern engine management systems.

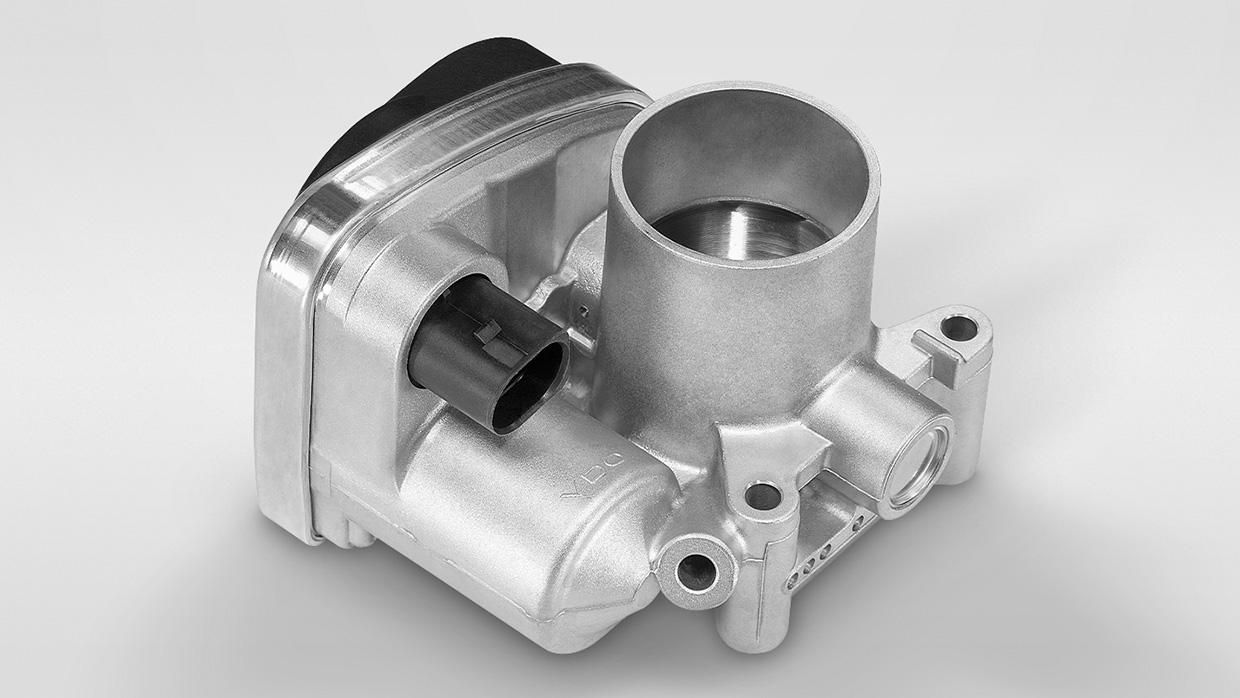

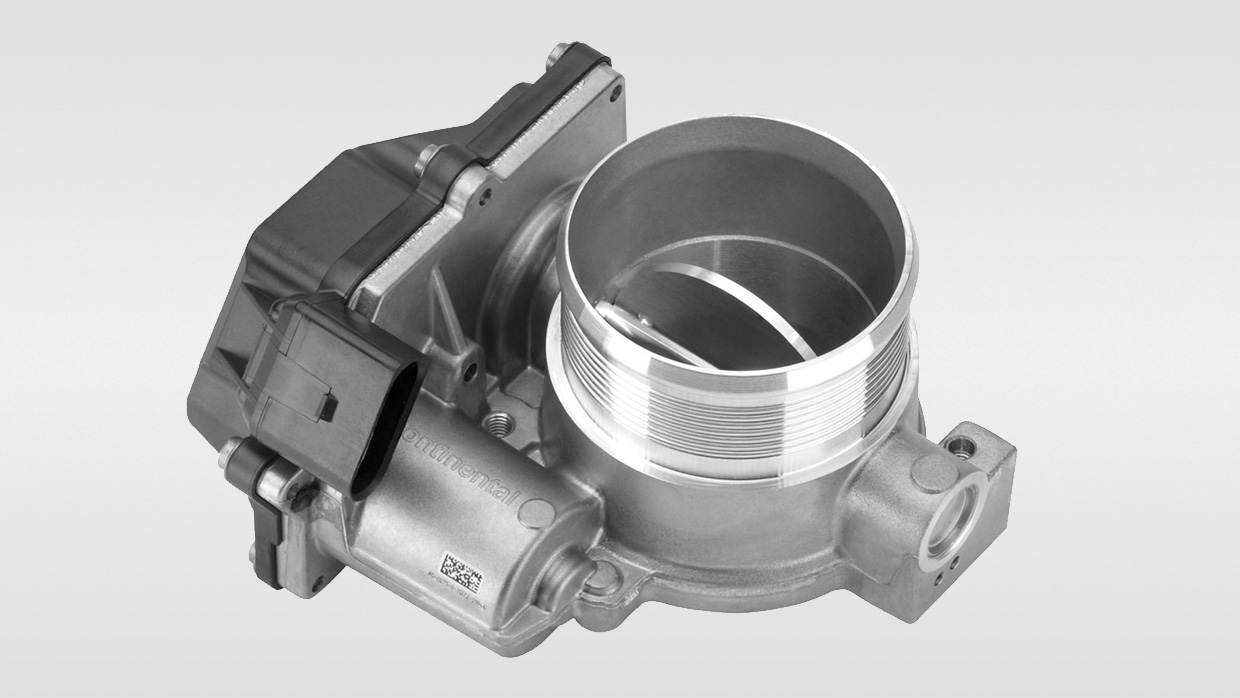

Throttle valves

The throttle valve electronics system, which transmits a control signal to the engine control unit at regular intervals, constantly compare all incoming information in order to calculate the best possible throttle valve position for consumption and exhaust emissions, so the throttle valve position is constantly fine-tuned.

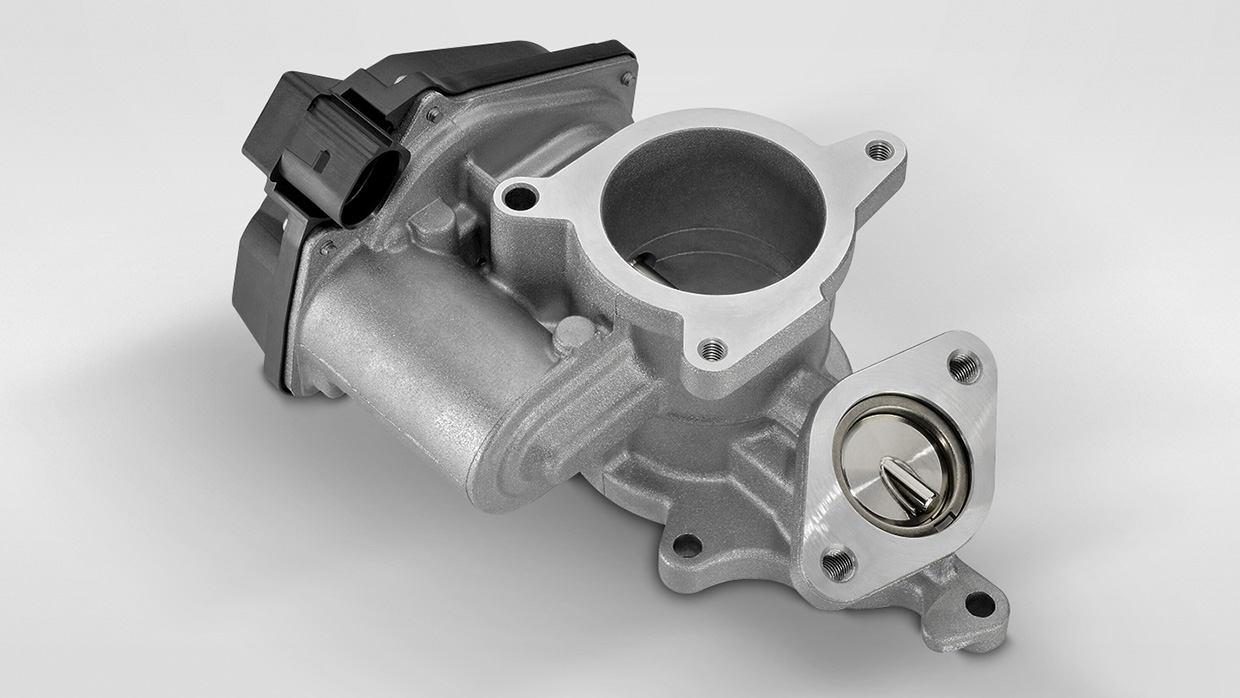

Air control valves

Our Air Control Valves (ACV) with or without integrated control electronics use electric motors to throttle the intake air in the intake of diesel engines. This achieves precisely controlled exhaust gas recirculation in accordance with the stricter exhaust gas standards and eliminate the disruptive “shudder” that occurs when a diesel engine shuts down.

Exhaust gas recirculation valves

Compared to conventional valves, electrically actuated exhaust gas recirculation valves enable an even more precise control of exhaust gas recirculation rates, making an important contribution to the fulfillment of the ever-stricter exhaust emission standards for diesel engines and direct-injection gasoline engines.

Dependably compliant with manufacturer specifications

VDO supplies engine actuators in OEM quality for a wide range of vehicles. You can rely on outstanding functionality, safety, dependability and service life performances.

Control

Control via separate position sensors and position control electronics

Reliability

A reliable and proven concept in production engines for passenger cars (gasoline)

Specification

Fulfillment of the OE specification

Experience

Decades of experience as a global OEM

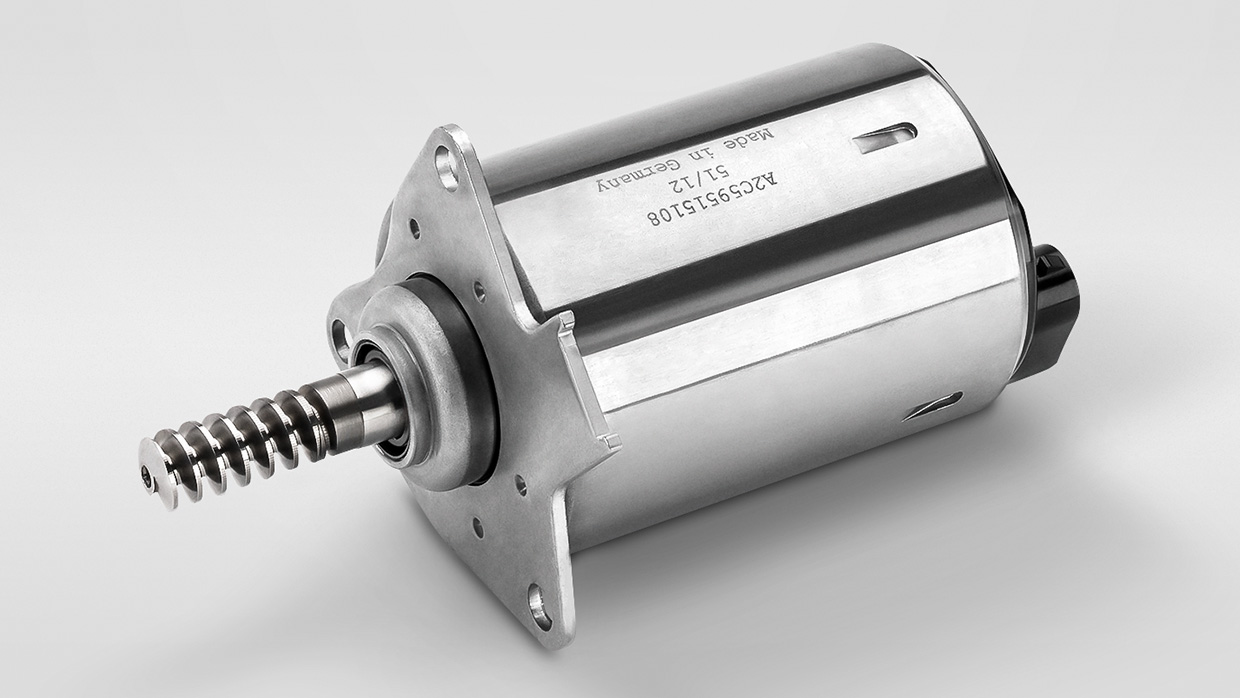

Variable lift control motors

VDO sensors and motors, e.g. for the Valvetronic system, increase vehicle performance and reduce fuel consumption in the gasoline engine by up to 10%. In the Valvetronic system, the air volume supply is controlled via variable valve lift, replacing the throttle valve functionality. The throttle valve is not totally omitted, however, since it takes over other functions such as emergency operation.

The high precision VDO adjustment motors control the valve lift electrically. They always bring the eccentric shaft, which changes the pivot point of the rocker arm, into the desired position, causing the inlet valves to open variably, depending on the load condition and engine speed. The rocker arm itself is driven mechanically by the intake camshaft. The VDO sensors accurately measure the current position of the eccentric shaft and send the measurements to the engine control unit (ECU).

VVT solenoid valves

At the same time, VVT (Variable Valve Timing) solenoid valves adjust the camshafts via changes in oil pressure, regulating the timing of the valves. The advantages here are optimized cylinder filling and engine performance at various engine speeds, plus reduced pollutant emissions.

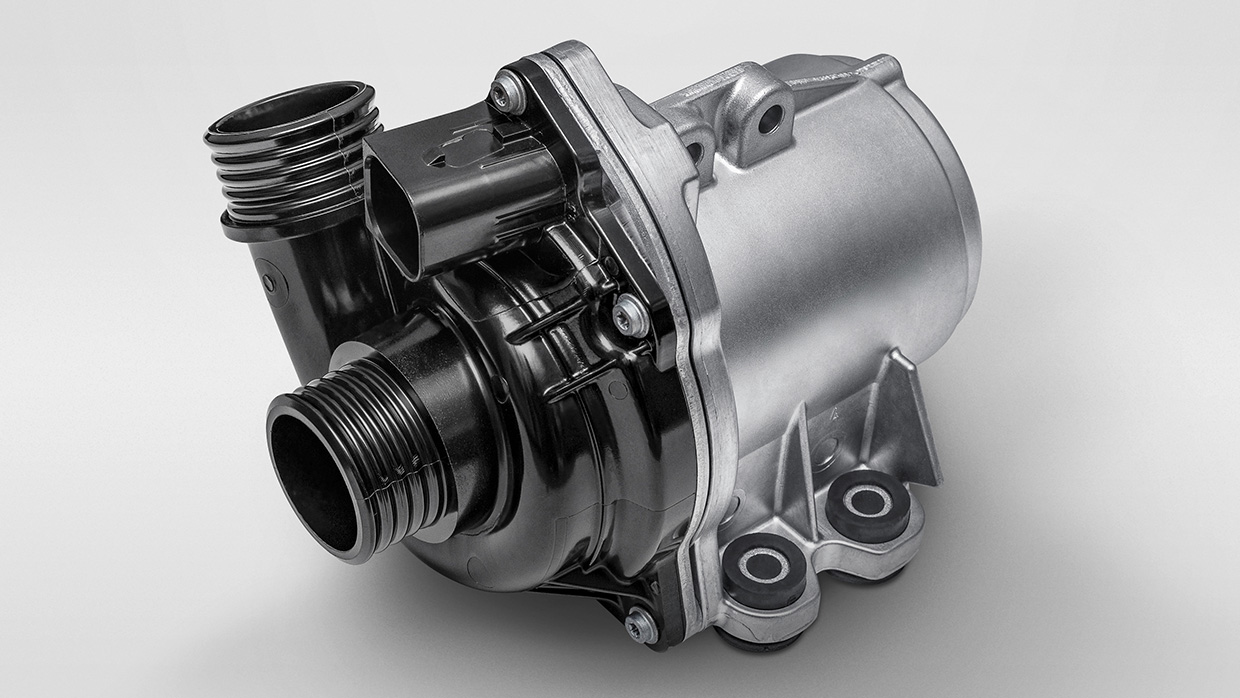

Electric water pumps

Our electric water pumps, each with an integrated control unit, ensure reliable, precise and demand-controlled engine cooling.

Catalog

Please see our online catalog for more information on this product that can be installed in your vehicle (passenger car).